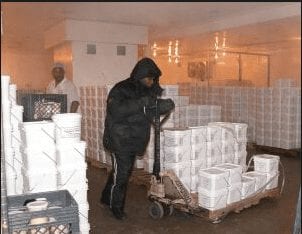

Warehouse management can be complicated, cold storage warehouse management, even more so…

Thanks to the advent and continuous development and improvement of warehouse software, companies can effectively manage supply chains by ensuring that warehouse software caters to the needs, challenges and opportunities within warehousing environments. Challenges commonly experienced are:

What challenges are unique to Cold Storage Environments?

While many of the challenges experience in cold storage warehousing environments are applicable to all warehousing environments, cold storage warehousing hosts unique challenges with regard to ensuring that all products are stored at the right temperature and some warehouses even host multiple temperature refrigeration in one environment.

- Managing the variable shelf life requirements by retailer (90 days for one, 60 for another).

- Doing the above and calculating transit time to ensure compliance.

- Managing export restrictions based on a production plant/slaughter house for foreign countries to ensure that the product from a single customer isn’t shipped from a banned plant.

- Managing temperature compliance coming in, and outbound and having the tools to do the inspections at the various stages.

- Serialized case codes/random weight product.

- Managing complexity and changing requirements for EDI as customers add clients.

- Billing and revenue tracking:

- Many billing rules varied by customer.

- Value added services:

- Light Kitting.

- Light mfg.

- Fulfillment and courier shipments.

Can Warehouse software solve all of the above?

A simple answer would be YES. However, warehouse software is not a one-size-fits -all solution and needs to be configured to your unique requirements. With regard to cold storage warehousing, warehouse software is absolutely crucial in implementing, controlling and monitoring, temperatures, product storage and shelf-life and ensuring that products entering and exiting the warehouse are delivered in timely and efficient manners to ensure fresh quality products for retailers.

Subsequently, the implementation of multiple-temperature warehousing environments, further stresses the need for adequate warehouse software to ensure that temperatures are well-controlled, product exiting the warehouse are aligned according to entering dates and shipping times and conditions adhere to temperature-control specifications.